Helifix Crack Stitching

Helifix Crack Stitching

Helifix Crack Stitching

Repairs and stabilises cracked masonry

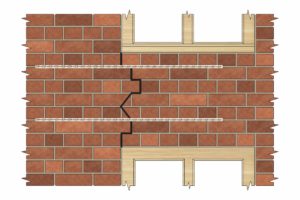

Helifix Crack Stitching repairs and stabilises cracked masonry using stainless steel Helifix HeliBars bonded into cut slots with Helifix HeliBond grout for a quick, simple, effective and permanent solution.

Send a product enquiryHelifix Crack Stitching repairs and stabilises cracked masonry using stainless steel Helifix HeliBars bonded into cut slots with Helifix HeliBond grout for a quick, simple, effective and permanent solution.

Cracked masonry is best stabilised by bonding Helifix HeliBar stainless steel bars into appropriate bed joints or cut slots. Tensile loads are redistributed along the masonry to minimise further developments of the crack which may occur with simple injection methods.

System Components

- 1m lengths of Helifix HeliBar

- Helifix HeliBond cementitious grout

- Mortar rake

- Mixing paddle

- Applicator with fitted applicator nozzle

Technical Details

- Available diameters – 4.5, 6 and 8mm

- Available in lengths of 1m, 1.5m and 2m

- Material – Austenitic stainless steel

- Vertical spacing – Every 4-6 brick courses (300-450mm)

- Depth of slot – Single skin / cavity wall 25-35mm Solid masonry 25-40mm

Repairing Cracks Near Corners & Openings

Where cracks are less than 500mm from an external corner or an opening, for example a window, at least 100mm should be bent around the corner and bonded into the return wall or bent and fixed into the reveal, avoiding any DPC membrane.

Where two or more cracks are close together these may be stitched using one continuous length of Helifix HeliBar which must be long enough to extend 500mm beyond the outer cracks. e.g. if there are three cracks, each 250mm apart, then the overall length of Helifix HeliBar required would be 1.5m.

The horizontal slot, normally the mortar bed, can be cut using a twin diamond blade chaser with vacuum attachment, an angle grinder or a mortar chisel.

All mortar must be removed, together with any loose debris, to ensure a sound bond. Prepare the slot with Helifix HeliPrimer WB or thoroughly wet the slot with clean water.

As standard, slots should be 10mm wide to accommodate the 6mm diameter Helifix HeliBar.

Helifix HeliBond grout is the recommended bonding agent. Helifix PolyPlus resin is used for smaller jobs and where loads are to be rapidly applied.

Additional Advice

- Where two or more cracks are close together these may be stitched using one continuous length of Helifix HeliBar which must be long enough to extend 500mm beyond the outer cracks. e.g. if there are three cracks, each 250mm apart, then the overall length of Helifix HeliBar required would be 1.5m.

- The horizontal slot, normally the mortar bed, can be cut using a twin diamond blade chaser with vacuum attachment, an angle grinder or a mortar chisel.

- All mortar must be removed, together with any loose debris, to ensure a sound bond.

- Prepare the slot with Helifix HeliPrimer WB or thoroughly wet the slot with clean water.

- As standard, slots should be 10mm wide to accommodate the 6mm diameter Helifix HeliBar.

- Helifix HeliBond grout is the recommended bonding agent. Helifix PolyPlus resin is used for smaller jobs and where loads are to be rapidly applied.

Installation

Enquire Now

Mandatory Fields*

Find an Approved Installer

Helifix’s Approved Installers ensure customers can be confident that repairs are carried out using the latest techniques to obtain an efficient, reliable, cost-effective solution.

Find an approved installer