Helifix DryFix Render Pinning

Helifix DryFix Render Pinning

Helifix DryFix Render Pinning

Special short tie for securing separated and unstable render

Helifix Render Pin is a special short version of the stainless steel Helifix DryFix helical pin, that are available for re-pinning separated, unstable and potentially dangerous loose stucco.

Send a product enquiryHelifix Render Pin is a special short version of the stainless steel Helifix DryFix helical pin, that are available for re-pinning separated, unstable and potentially dangerous loose stucco. Typically the render is 20-65mm thick but this can vary greatly between 12mm and 80mm. Breakdown of the bond between the stucco and back-up material can occur for various reasons but once delaminated it is likely to become increasingly unstable, resulting in cracks and bulges. These in turn encourage water penetration while wind loads tend to loosen the stucco even further. Mosaic tile finishes can easily become loose and fall away.

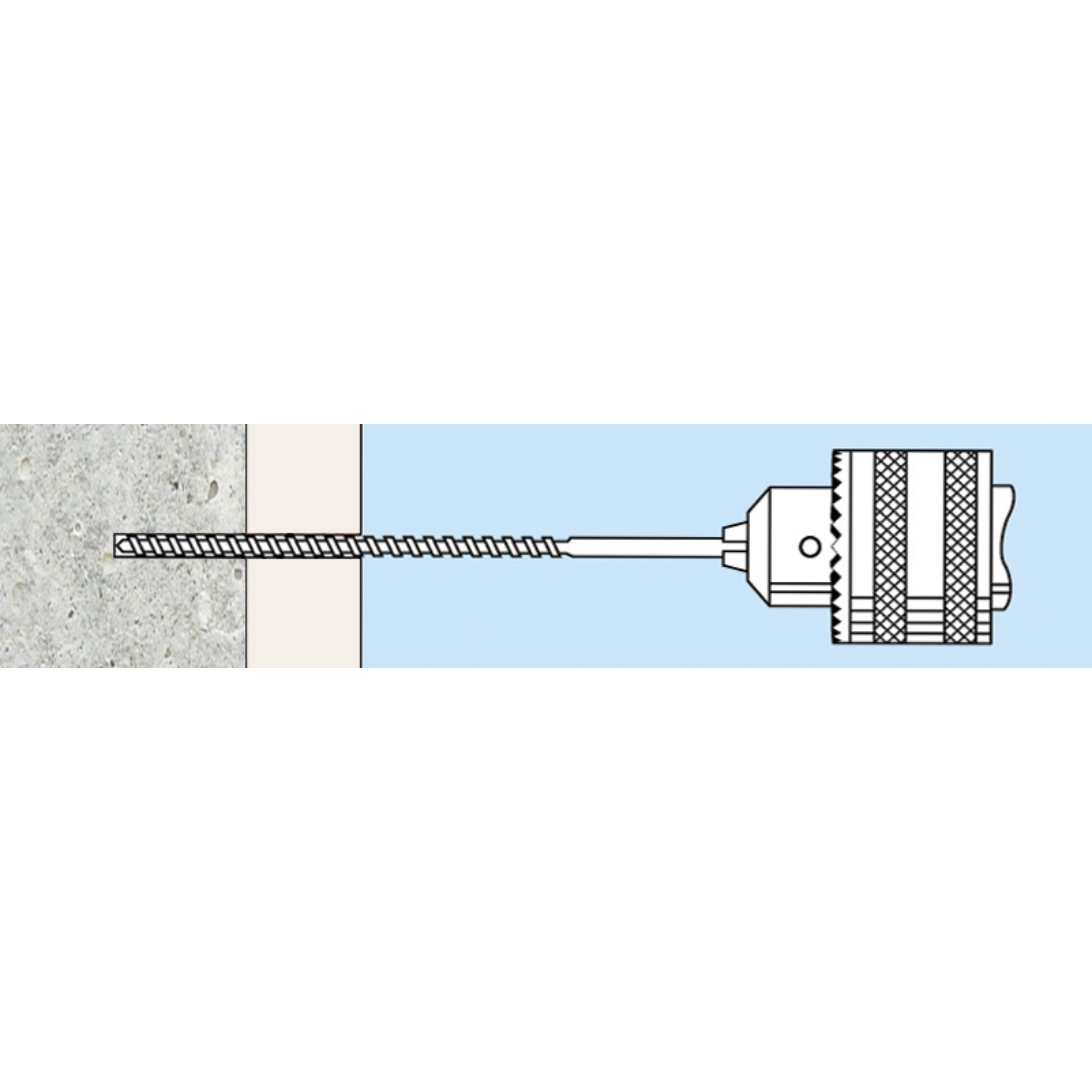

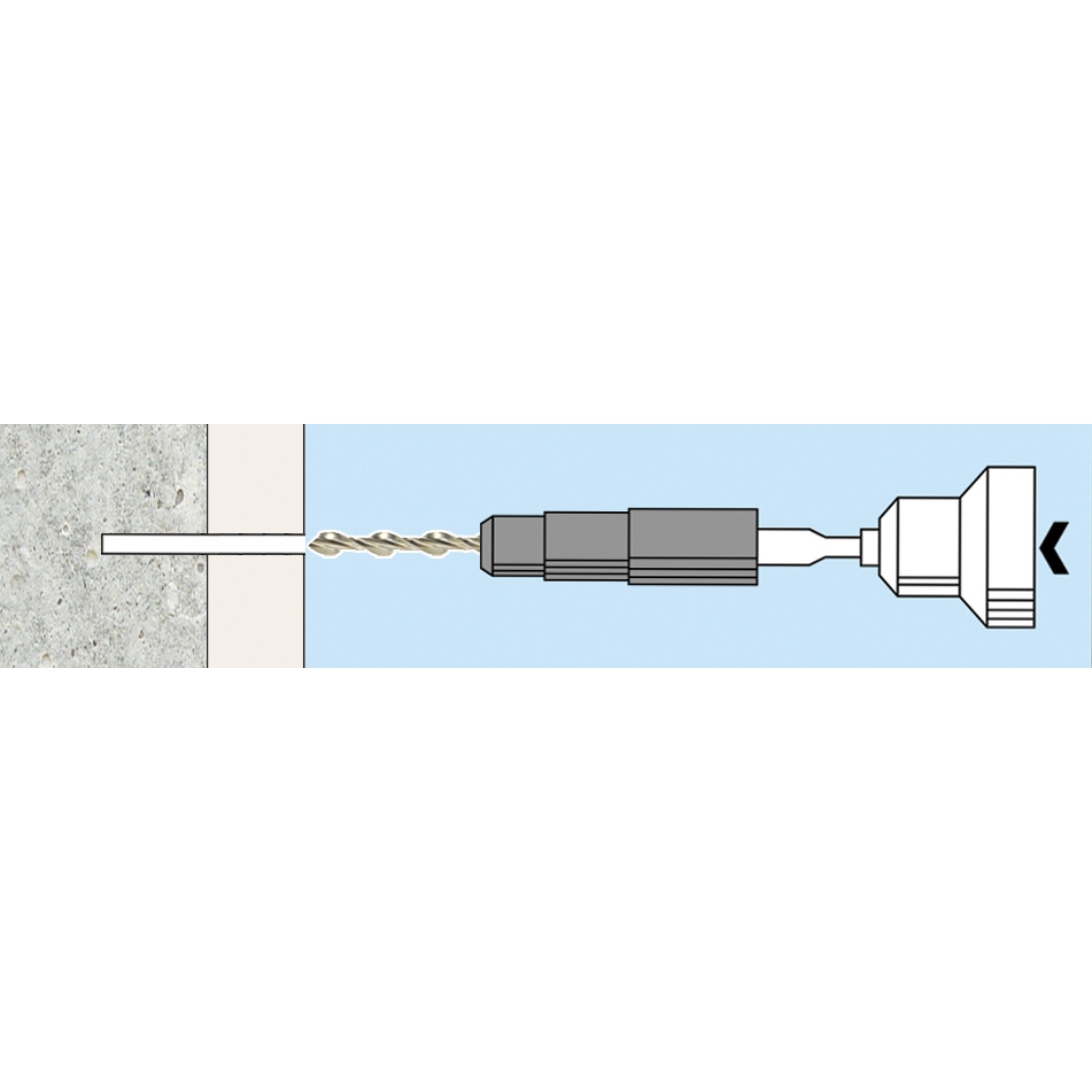

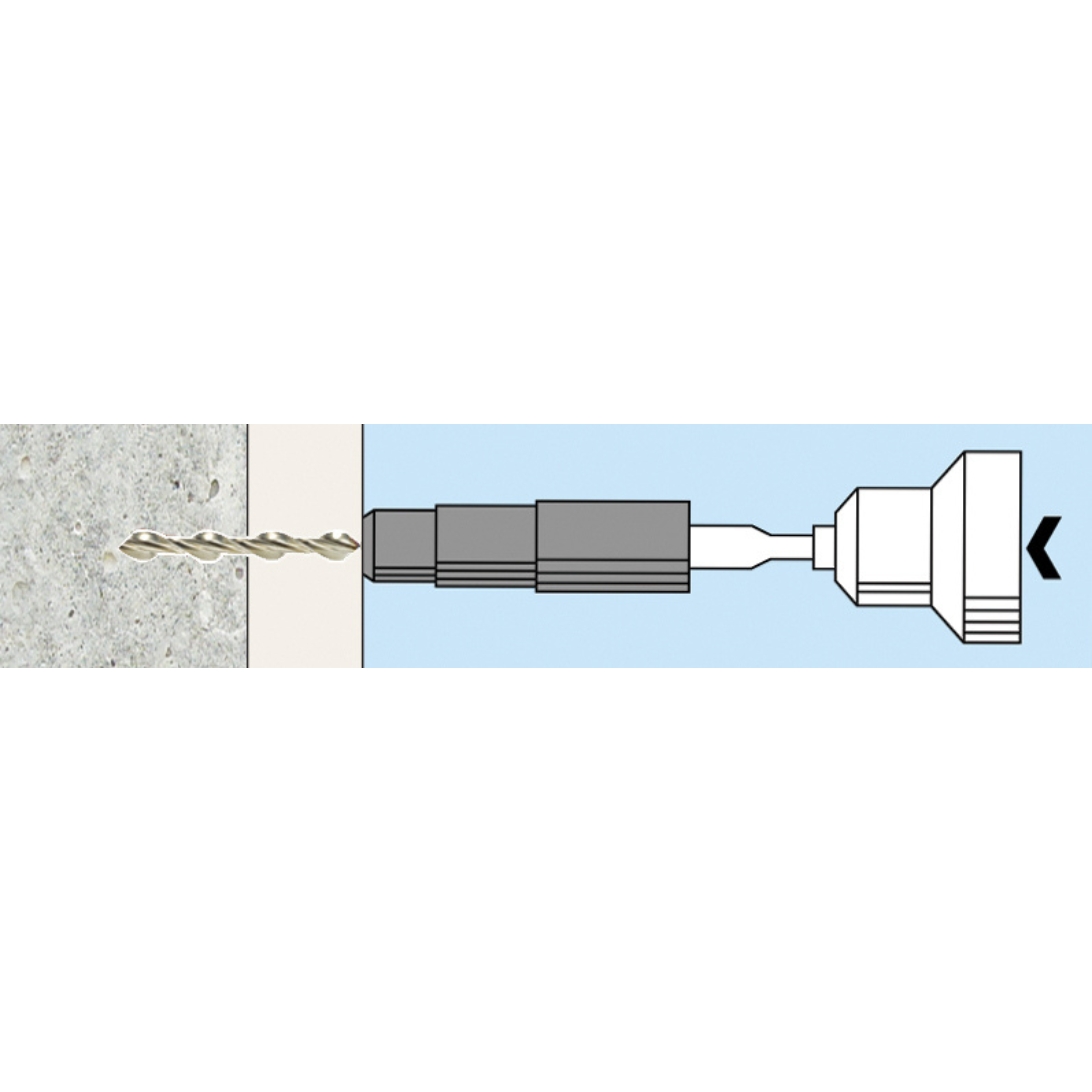

Installed in the same way as standard Helifix DryFix ties, re-pinning is a far simpler and more cost-effective method of stabilising the stucco than traditional solutions such as hacking off and re-rendering or chemical anchoring with large pins.

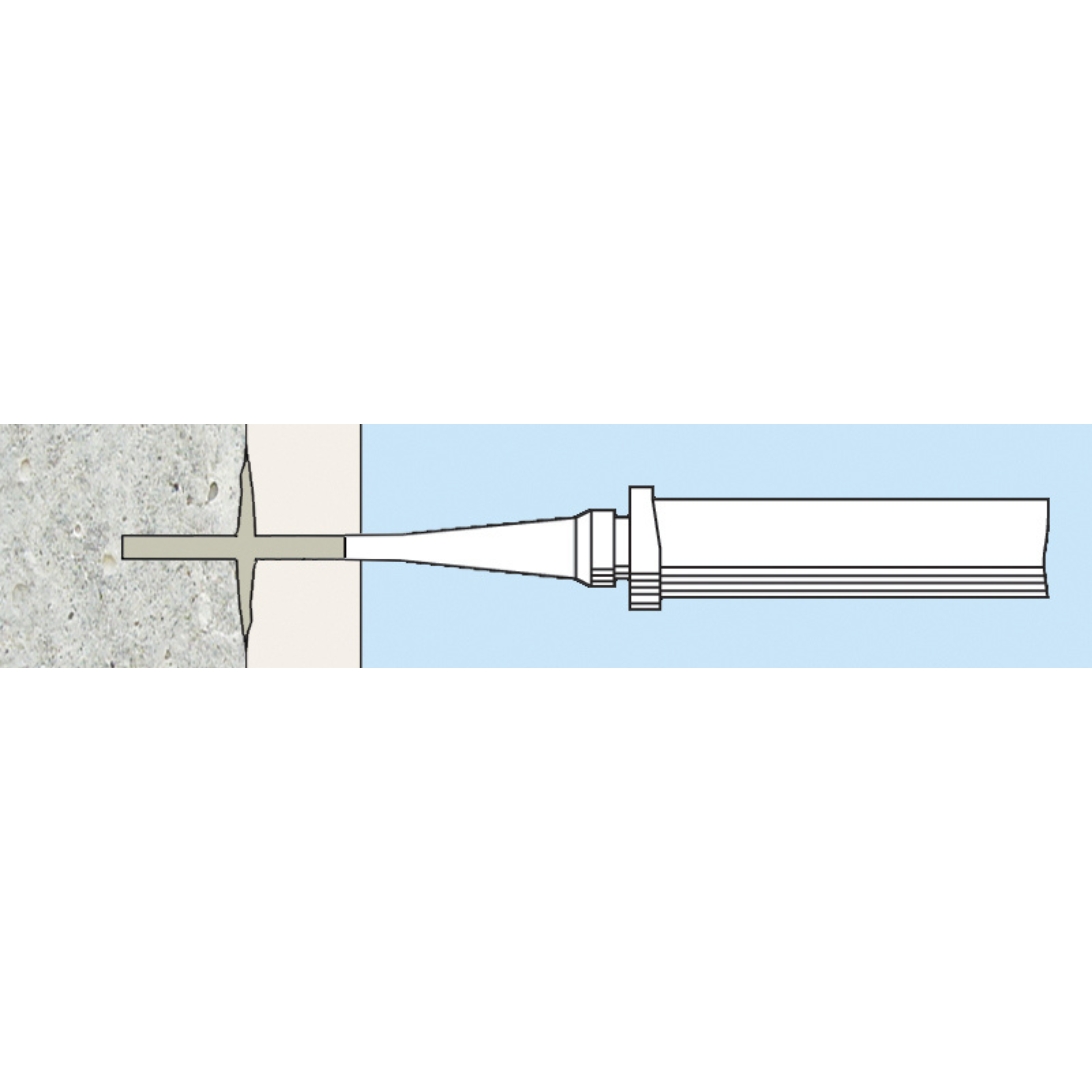

Helifix DryFix pinning simply requires drilling a small pilot hole – usually 6mm – and driving an 8mm grade 316 stainless steel helical pin through the stucco and into the back-up material. The outer end of the pin is left recessed just below the surface allowing the hole to be caulked to prevent any water penetration and provide a good surface for repainting or mosaic tiling as appropriate.

The versatile Helifix DryFix system is a reliable, economical, high quality alternative to traditional repair methods of chemical anchoring or hacking off and re-rendering.

Applications

- Re-pinning separated, unstable and potentially dangerous loose render.

- Where buildings are often coated with a hard render, keyed to the back-up material by means of a splatter dash application, which is then painted or covered with small tiles to achieve a waterproof finish.

- Typically the render is 20-65mm thick but this can vary greatly between 12mm and 80mm.

- Far simpler and more cost-effective method of stabilising the render than traditional solutions such as hacking off and re-rendering or chemical anchoring with large pins. (See 1988 report by Frank Jones).

Installation

Enquire Now

Mandatory Fields*

Find an Approved Installer

Helifix’s Approved Installers ensure customers can be confident that repairs are carried out using the latest techniques to obtain an efficient, reliable, cost-effective solution.

Find an approved installer