Helifix HeliBar Remedial

Helifix HeliBar Remedial

Helifix HeliBar Remedial

Helical stainless steel reinforcing bar for masonry repair and new construction

The Helifix HeliBar is a helical stainless steel reinforcing bar, with substantial tensile properties, used for strengthening and stabilising masonry in both new build and remedial situations.

Send a product enquiryThe Helifix HeliBar is a helical stainless steel reinforcing bar, with substantial tensile properties, used for strengthening and stabilising masonry in both new build and remedial situations.

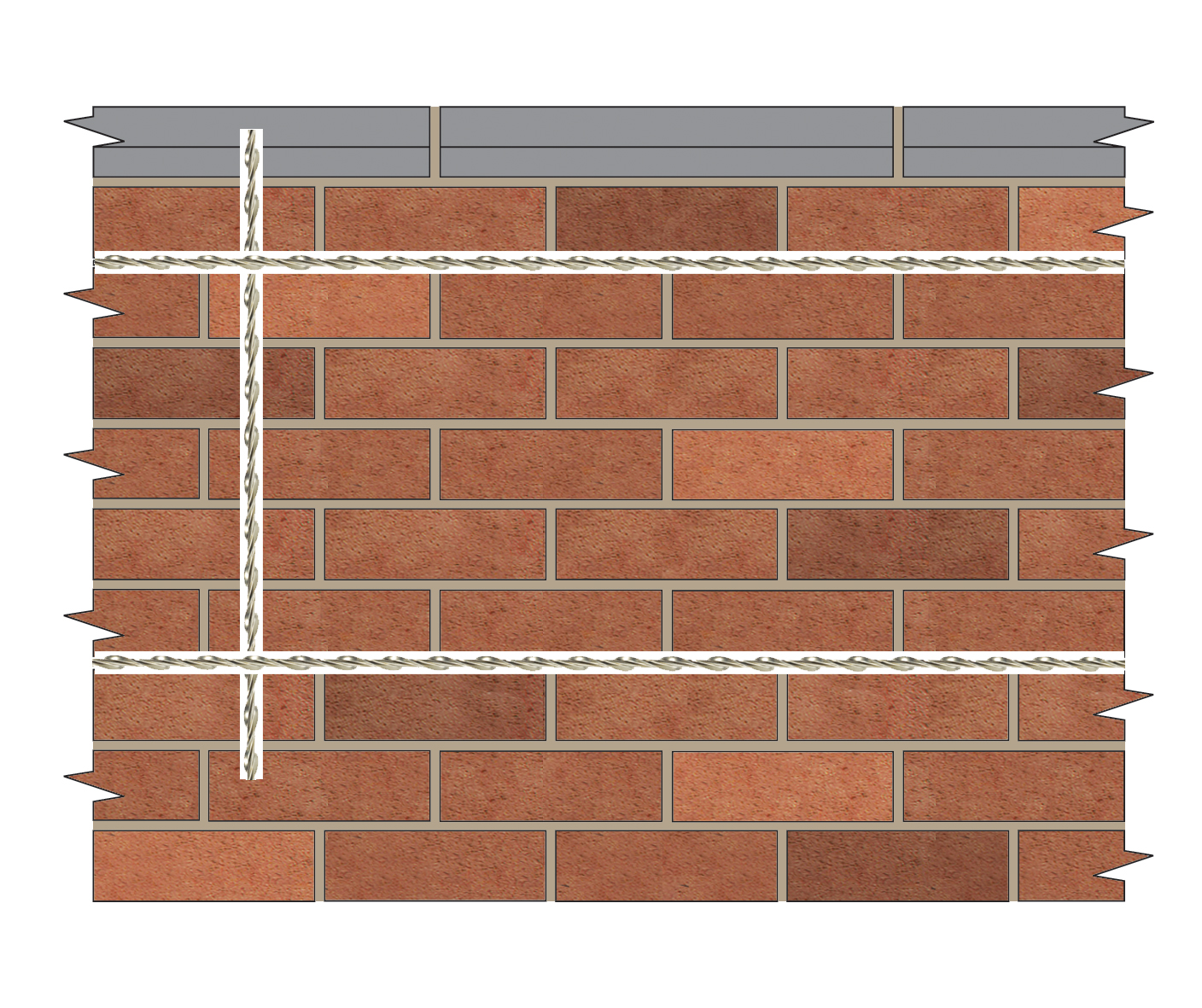

Helifix HeliBars are bonded into cut slots at pre-determined levels in the masonry using Helifix HeliBond thixotropic cementitious grout, it is the composite action between the Helifix HeliBars and Helifix HeliBond that provides the core element of the Helifix Helibeam System, making it such a versatile, reliable and successful masonry repair system.

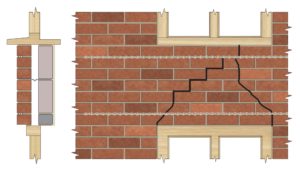

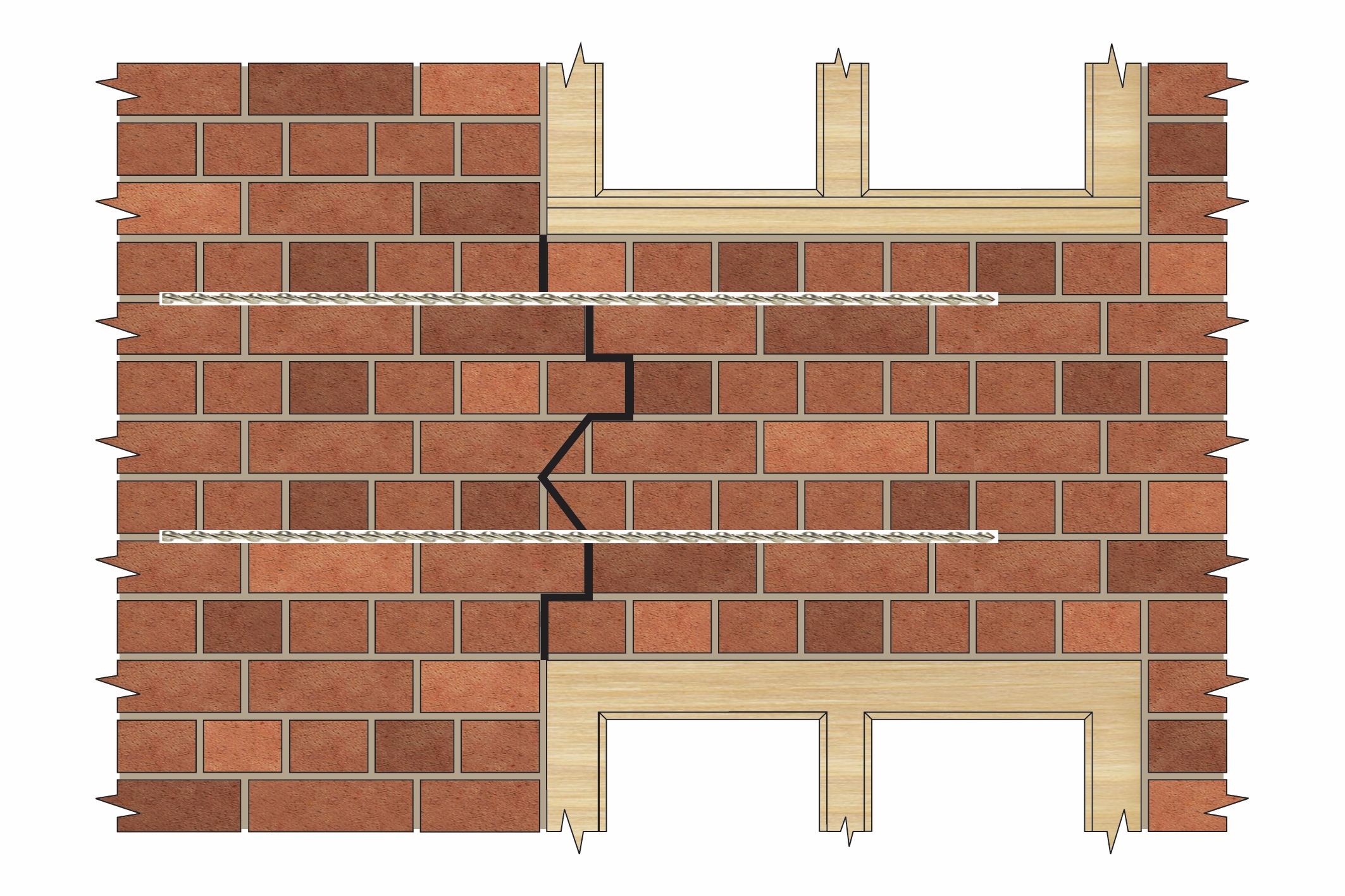

The length of the Helifix HeliBar varies depending upon the application. Longer lengths are used, normally in pairs, to form masonry beams that secure large areas of masonry, distributing the structural loads and overcoming various problems caused by foundation movement. They are also installed in the existing masonry to unobtrusively create or reinstate failed lintels. In shorter 1m lengths, Helifix HeliBars are used individually to perform reliable and permanent crack stitching.

Helifix HeliBar starts as round stainless steel wire with a typical 0.2% proof stress of 500N/mm² but after the cold forming manufacturing process that creates the helical hi-fin design, this more than doubles to around 1100N/mm². This means that Helifix HeliBar, with its relatively small diameter, provides substantial tensile properties to the masonry, particularly when combined with Helifix HeliBond grout which locks between the fins and bonds to the masonry. Consequently, the well proven Helifix Helibeam System has a variety of remedial and new build applications.

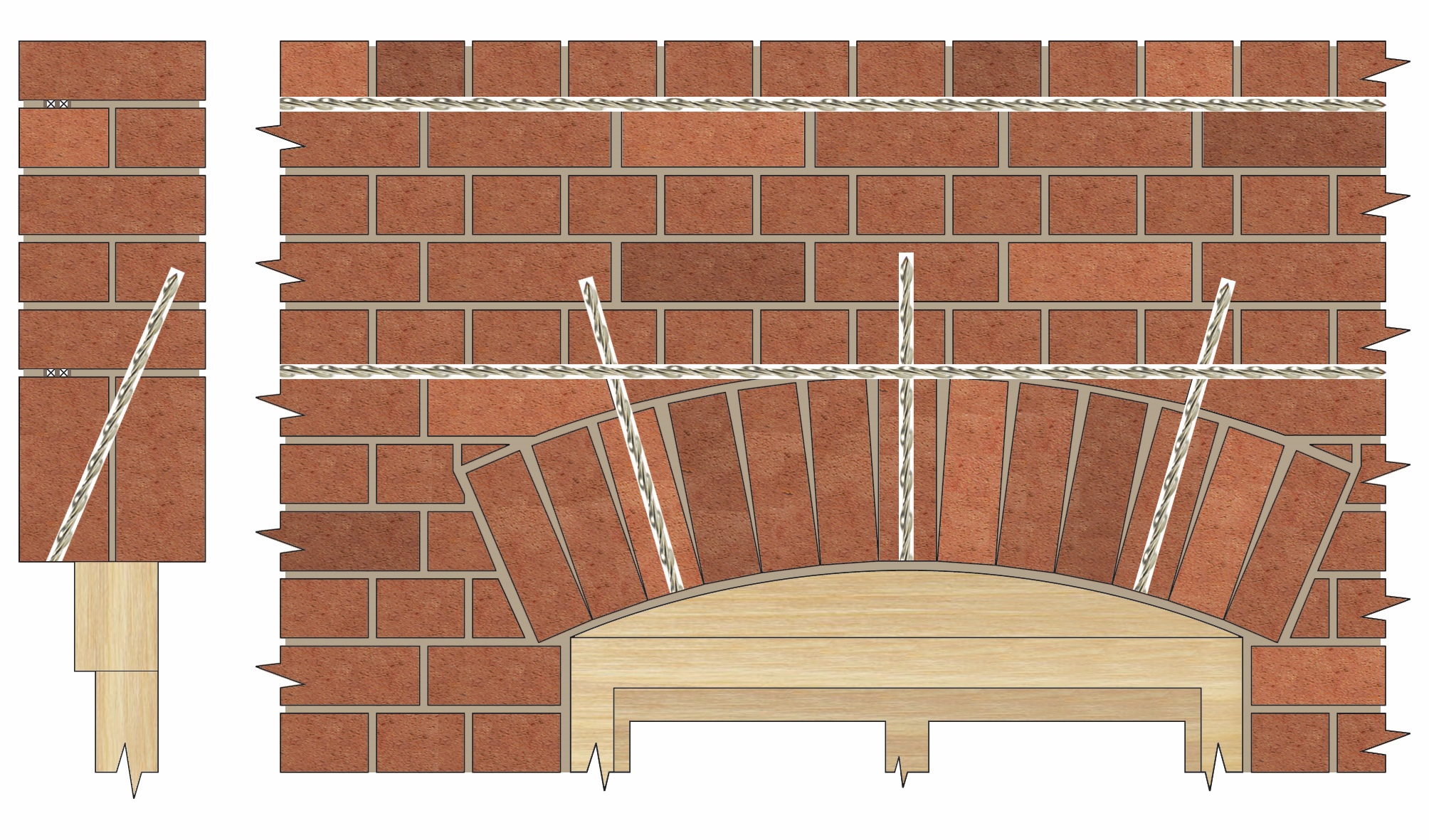

Creating or repairing flat arch lintels

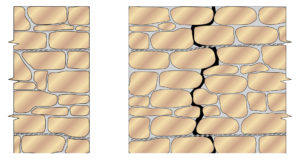

Crack stitching in a corner of a stone wall

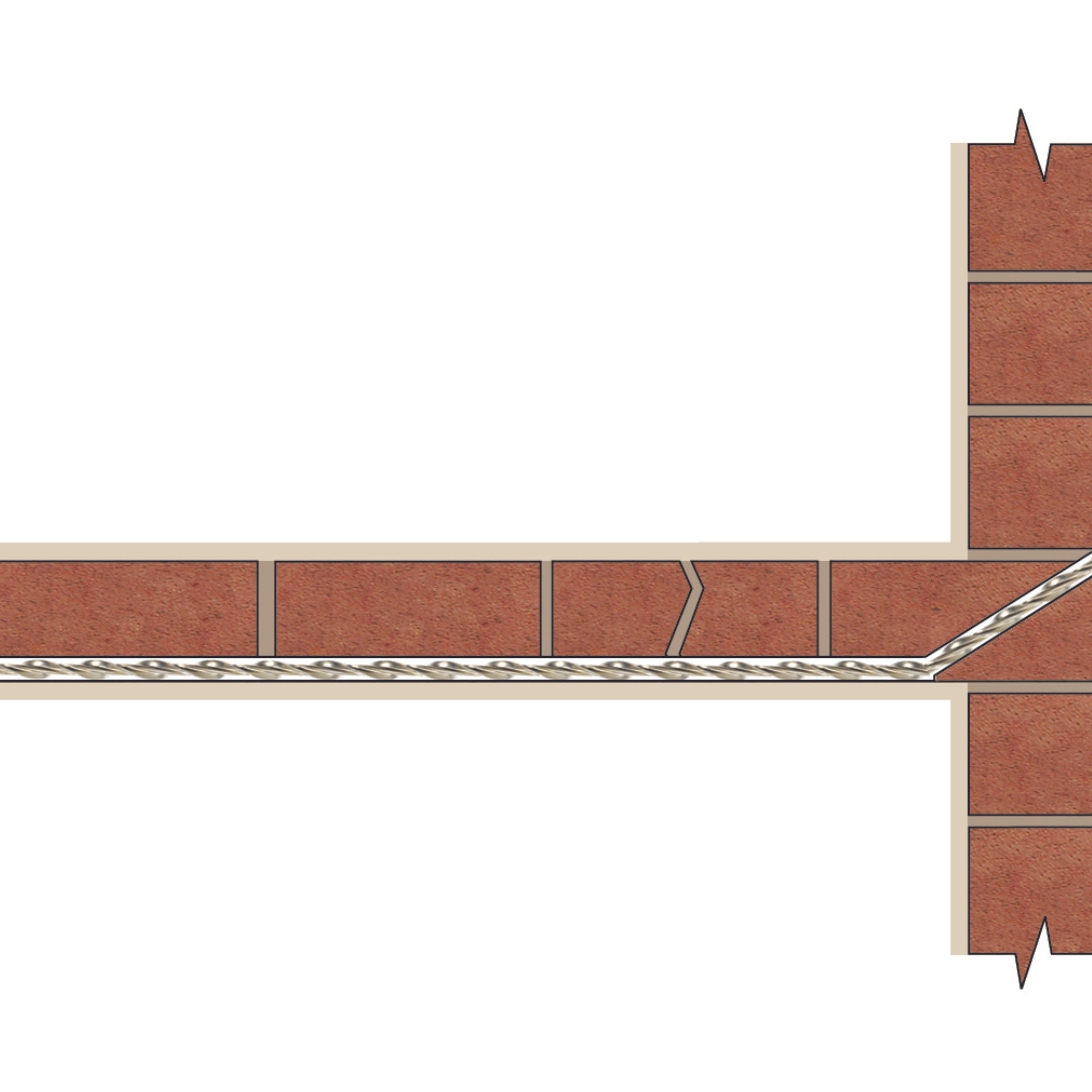

Creating movement joints

Using 400mm long bars, installation is very similar to crack stitching. The bar is installed across the joint, as with cracks, but is only bonded at one end. The other end is allowed to move freely by inserting it into a sleeve which is bonded into the masonry.

Applications

- Crack stitching

- Lintel repair and creation

- Forming deep masonry beams

- Horizontal structural restraint (when used with BowTie systems)

- Reconnecting separated walls

- Securing parapet walls

- Support existing masonry when creating new openings

- For reinforcing new build masonry

- Creating movement joints

- Seismic upgrades for existing masonry

- Repairing bridges, tunnels and arches

Crack Stitching

Lintel Reinstatement

Securing Parapet Walls

Reconnecting separated walls

Installation

Enquire Now

Mandatory Fields*

Find an Approved Installer

Helifix’s Approved Installers ensure customers can be confident that repairs are carried out using the latest techniques to obtain an efficient, reliable, cost-effective solution.

Find an approved installer