Helifix PatchPin

Helifix PatchPin

Helifix PatchPin

Concrete patching pin

Helifix PatchPin is a short stainless steel helical pin that provides a strong mechanical key when patch repairing reinforced concrete.

Send a product enquiryHelifix PatchPin is a short stainless steel helical pin that provides a strong mechanical key when patch repairing reinforced concrete.

System Components

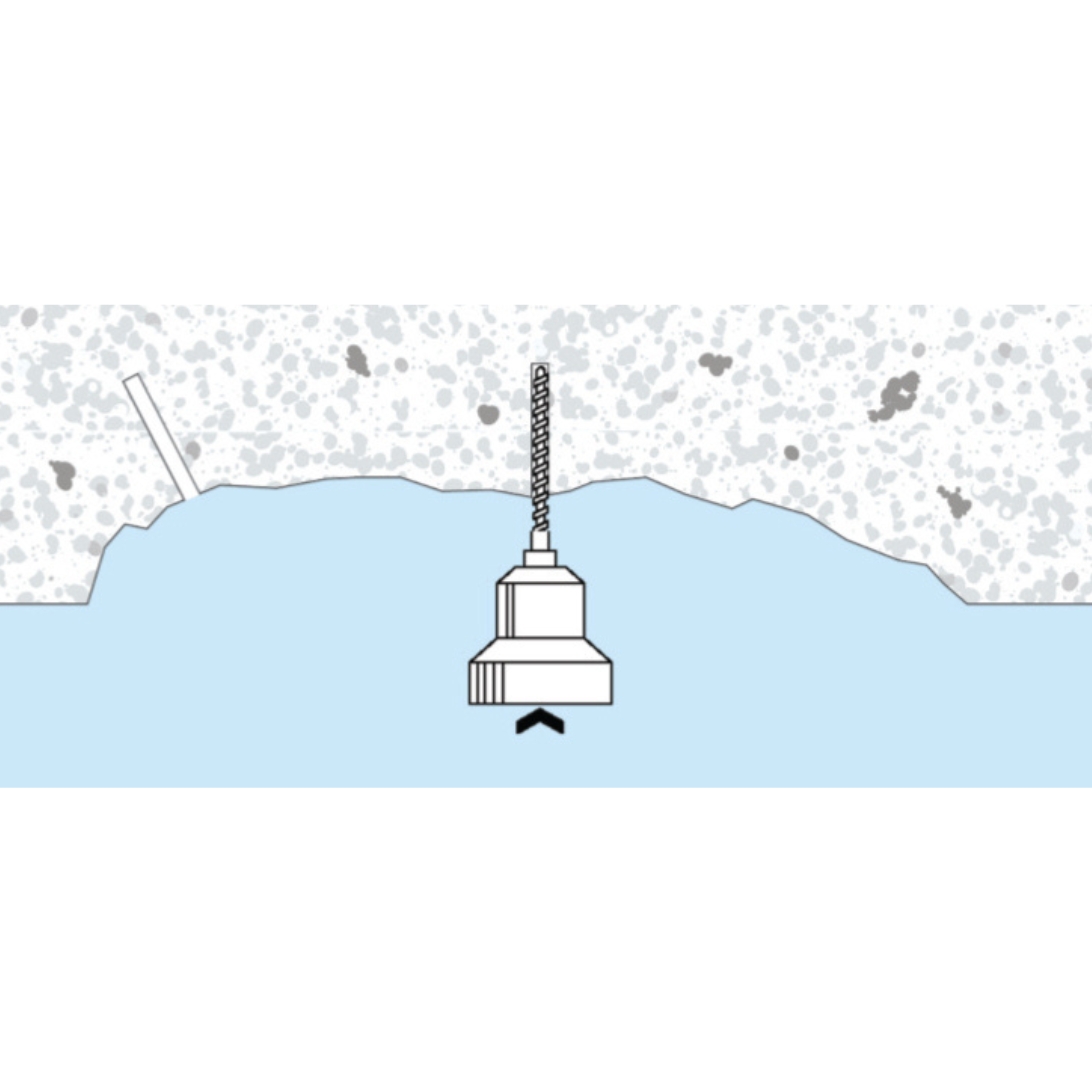

- Helifix PatchPins

- Power drill support

- Drill bit

Applications

Stainless steel helical pin for providing a strong mechanical key when patch repairing reinforced concrete

Additional Advice

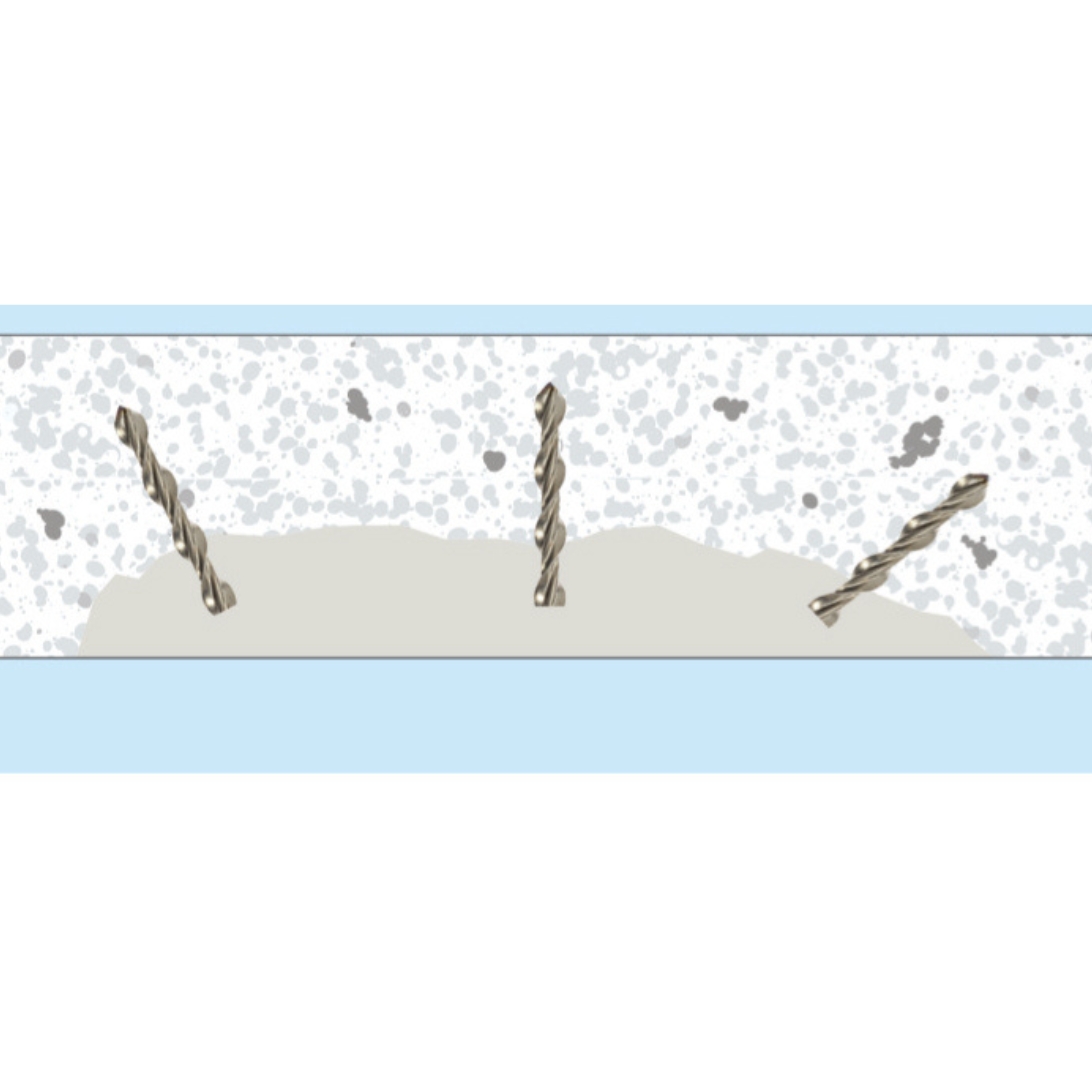

- Pin spacing and position may be varied to suit site conditions

- Pins are to be installed approx. 50mm from the edge of the patched area

- Intermediate pins should be at 150-200mm centres. Extra pins may be used at the discretion of the site management or the engineer in charge

- Pins should be applied at not less than two pins per patch

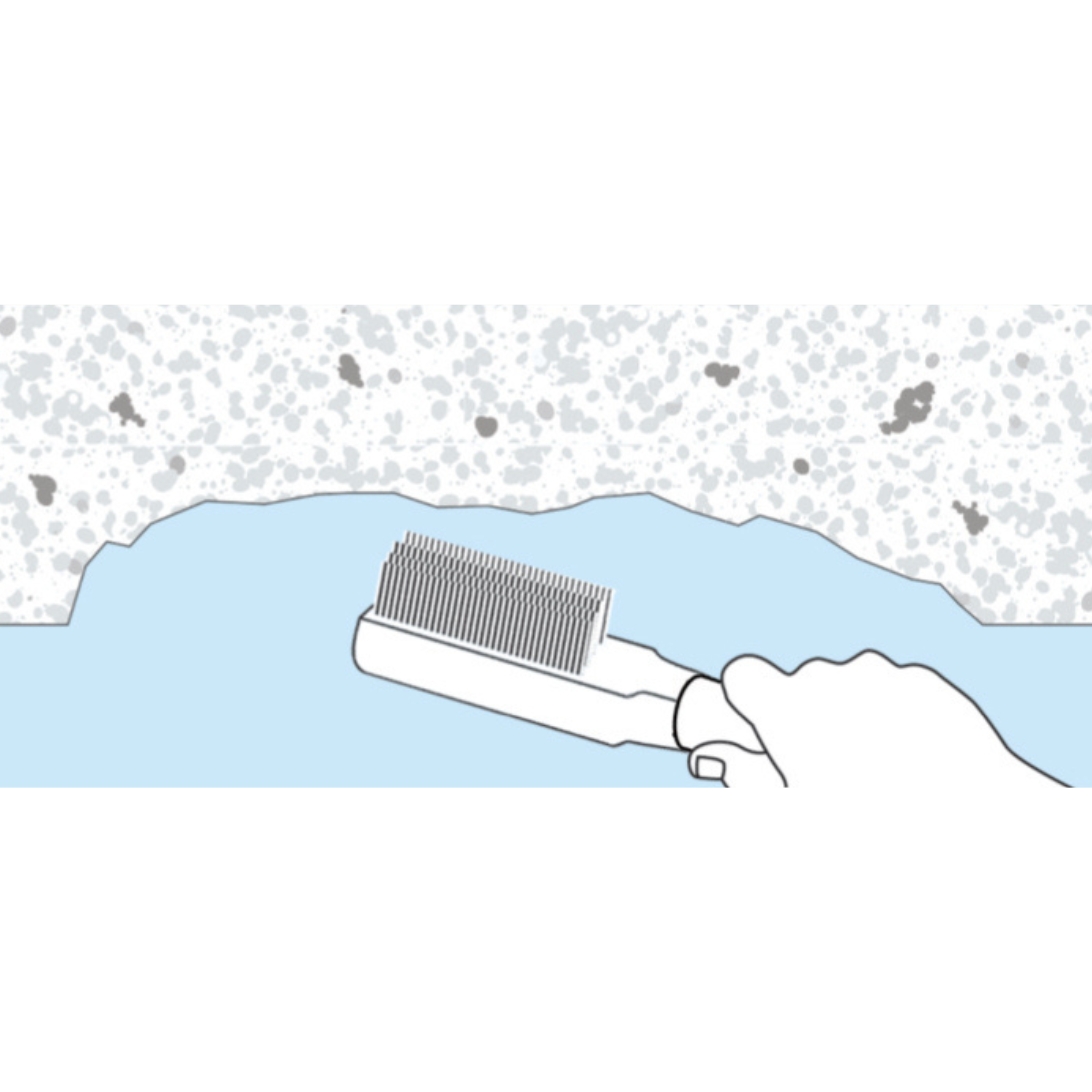

Installation

Enquire Now

Mandatory Fields*

Find an Approved Installer

Helifix’s Approved Installers ensure customers can be confident that repairs are carried out using the latest techniques to obtain an efficient, reliable, cost-effective solution.

Find an approved installer