Helifix SockFix

Helifix SockFix

Helifix SockFix

Mechanical grouted sock anchor systems for stabilising damaged masonry

Our extended range of Helifix SockFix mechanically grouted sock anchor systems ensures a solution for a wide variety of applications and repair solutions.

Send a product enquiryOur extended range of Helifix SockFix mechanically grouted sock anchor systems ensures a solution for a wide variety of applications and repair solutions. The systems comprise of a grout-filled sock that combines with a bar in a composite action which expands to form a strong chemical/mechanical bond with the substrate.

The Helifix SockFix systems are used in light and heavy duty, high load applications. Including as a wall tie/consolidation tie, stabilising rubble-filled walls, securing external walls to hollow concrete floor slabs, stitching cracked solid and multi-leaf walls and securing unstable parapet walls and arches.

The most suitable Helifix SockFix type for your application will be identified by our Leviat Technical Area Managers or one of our Helifix Approved Installers.

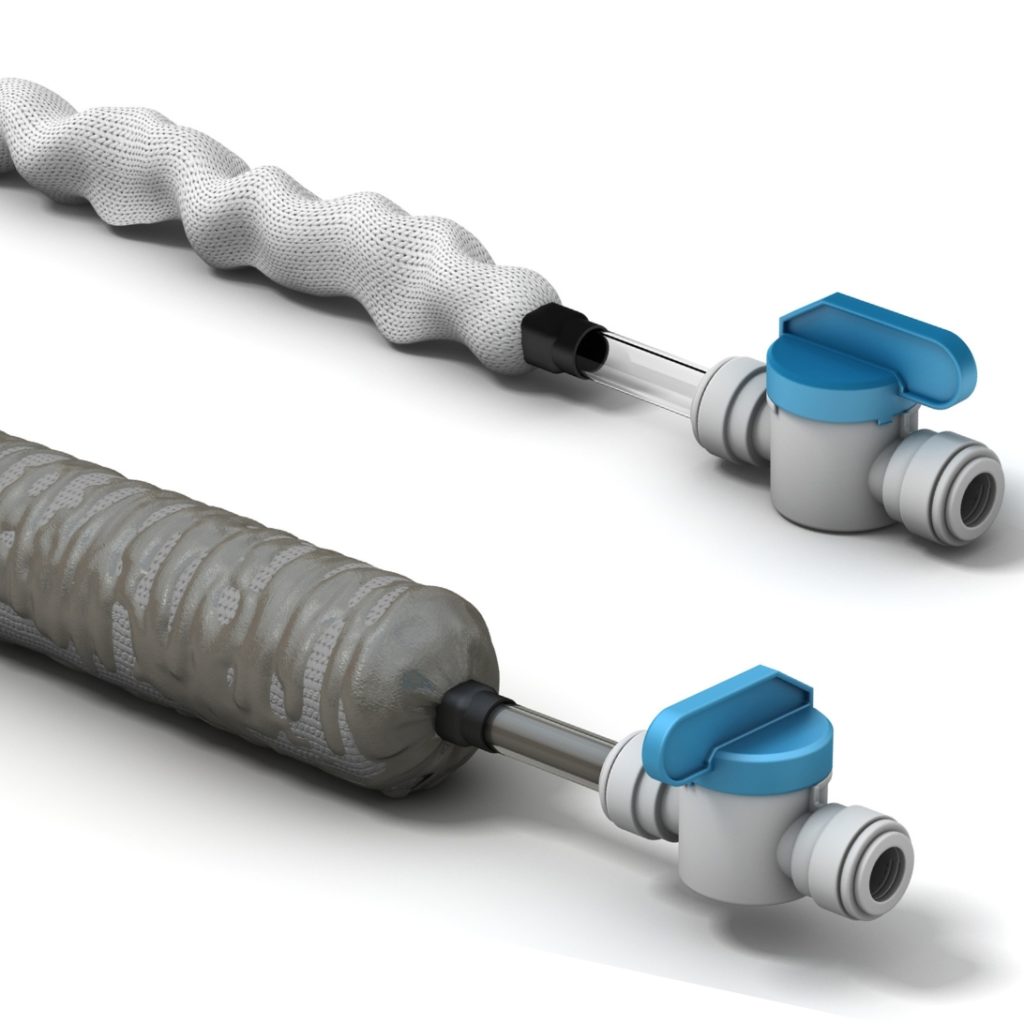

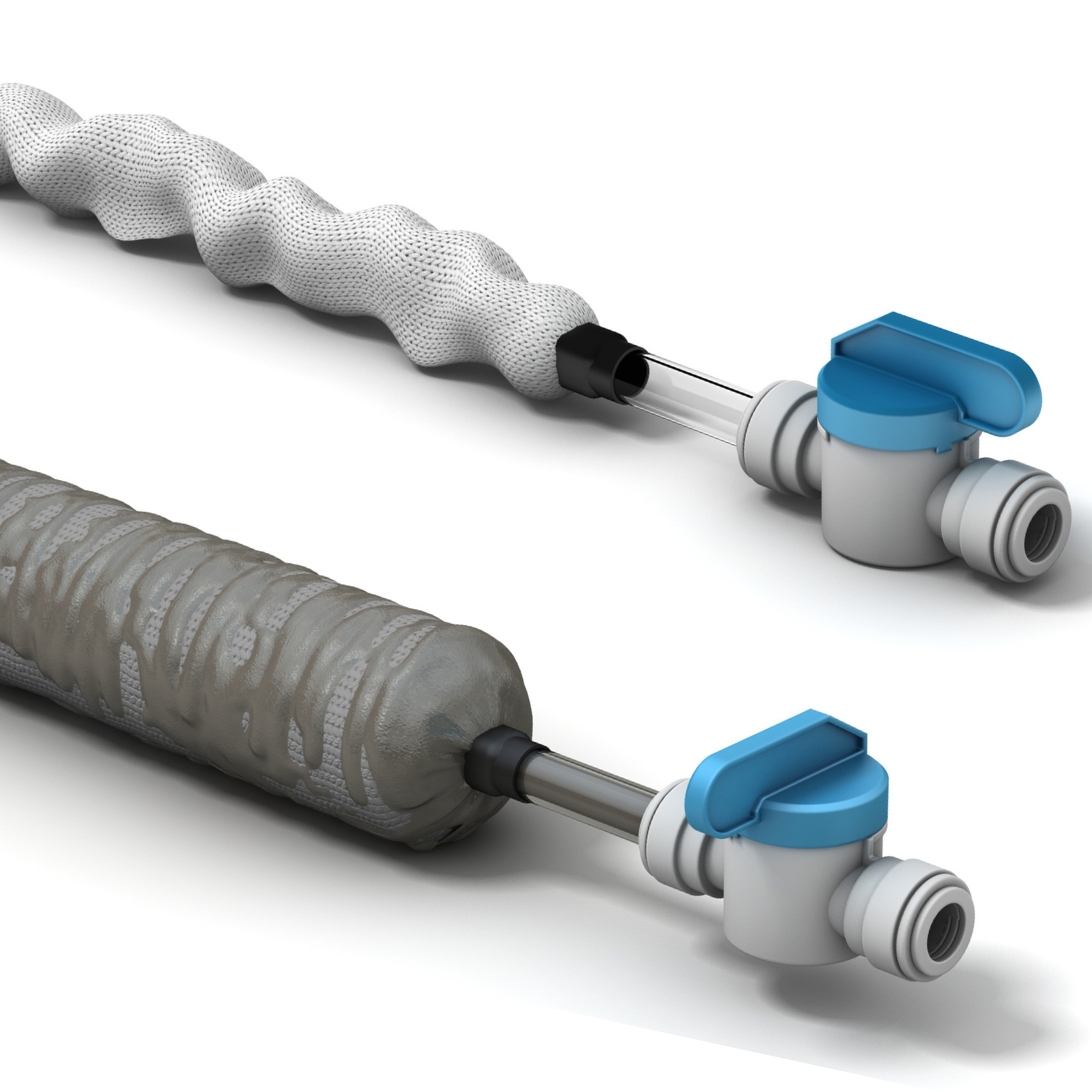

SockFix HDA before and after inflation

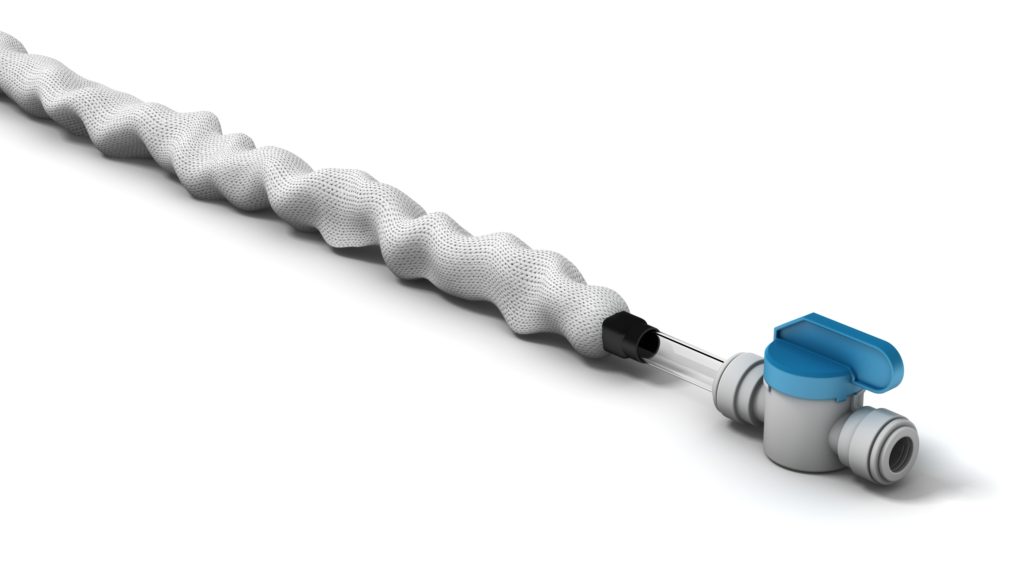

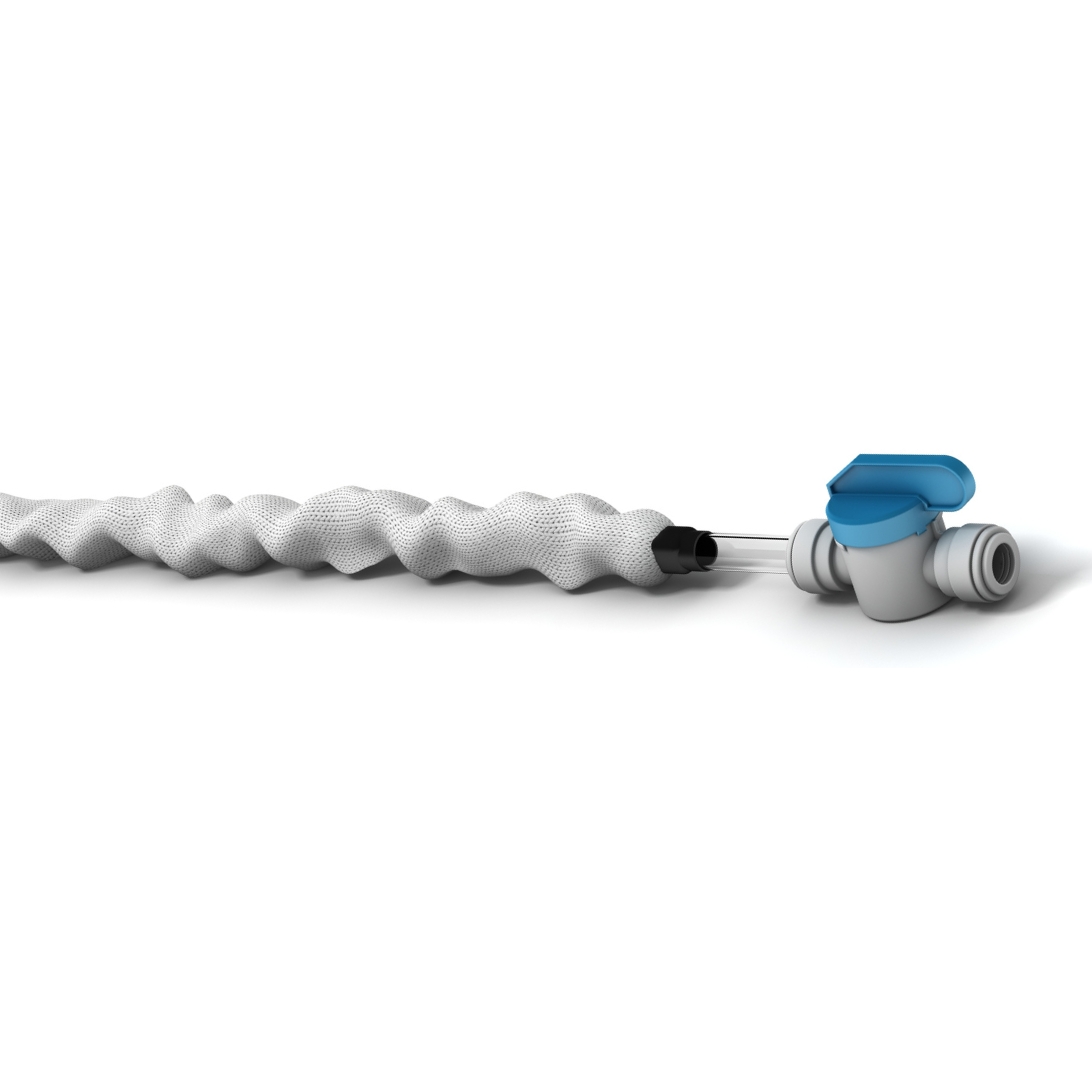

SockFix CCA

SockFix TSA connected using tension couplers

Technical Data

| Helifix SockFix Types | ||

| Helifix SockFix HDA, LDA, TSA | Helifix SockFix CCA | Helifix SockFix SSA |

| Materials: Grade 304 (1.4301) austenitic stainless steel threaded bar, heavy duty mesh fabric sleeve | Materials: Grade 304 circular hollow section, heavy duty mesh fabric sleeve | Materials: Grade 204 square hollow section, heavy duty mesh fabric sleeve |

| Bar Diameters: 8mm to 10mm, 10mm to 12mm, 12mm to 16mm, 16mm+ | Circular Hollow Section Size: 10mm, 12mm, 16mm, 18mm | Square Hollow Section Size: 15mm x 15mm, 20mm x 20mm, 30mm x 30mm |

| Length to be used: As specified | ||

| Standard lengths: Up to 3m. Couplers used to form longer lengths | ||

Applications

- Grout-filled sock combines with bar in a composite action and expands to form a strong chemical/mechanical bond with the substrate

- For heavy duty, high load, applications

- For securing external walls to hollow concrete floor slabs

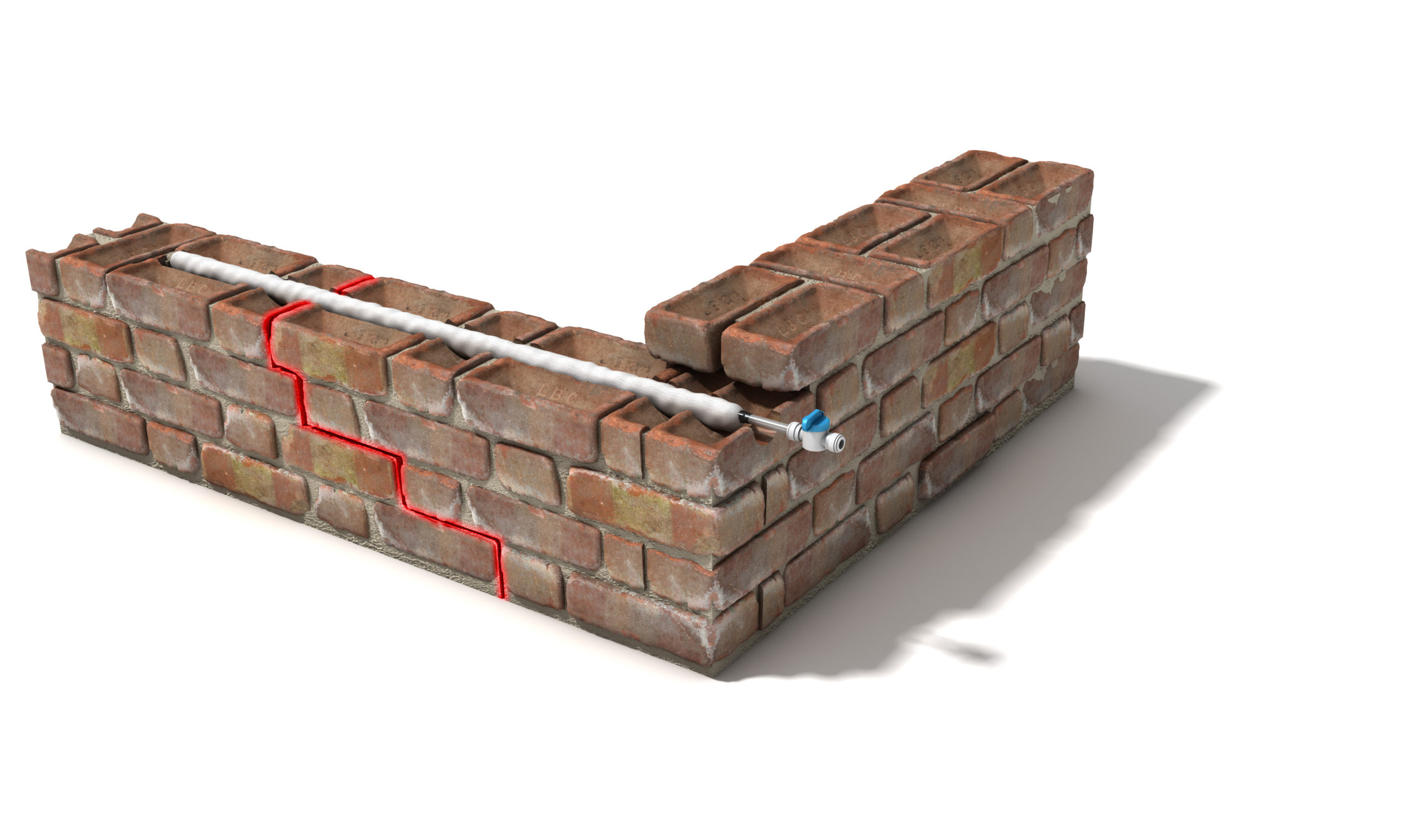

- For stitching cracked solid and multi-leaf walls

- For stabilising rubble-filled walls

- For securing unstable parapet walls and arches

- Where high levels of performance are required in bending

- Where drilling lengths in excess of 1m are required

Please note: repair details CS15, CS16 and RW07 relate to Helifix SockFix applications and can be downloaded here.

Stitching a cracked solid wall.

Stabilising a cracked rubble-filled wall.

Securing an external wall to a hollow concrete floor slab.

Installation

Enquire Now

Mandatory Fields*

Find an Approved Installer

Helifix’s Approved Installers ensure customers can be confident that repairs are carried out using the latest techniques to obtain an efficient, reliable, cost-effective solution.

Find an approved installer