Before windows are replaced, it is essential to check the condition of the lintels to assess their structural stability.

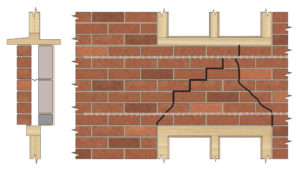

If there are cracks running from a window’s top corners, often at 45°, the likelihood is that the lintel has failed.

Sometimes the lintel is simply weak and needs reinforcing to ensure there is no movement and in some cases there is no lintel at all and the masonry has simply been supported by the existing window frame. In this situation a new lintel must be installed or created.

Creating lintels in a cavity wall

Traditionally, the brickwork above a window would be removed and a new concrete lintel or steel angle installed. This is time consuming, expensive and, with three new courses of brickwork, visually unappealing. It is also extremely disruptive for the residents as it involves having mechanical props both internally and externally to support the masonry during lintel installation.

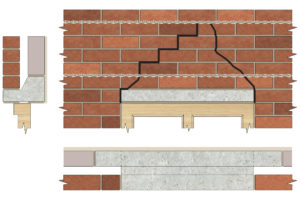

Overcoming rotating boot lintels

The Helifix Helibeam system overcomes all these difficulties by using the existing masonry. It is quick, simple, reliable, economical and non-disruptive. Mortar beds are channelled-out at two levels above each window and pairs of stainless steel Helifix HeliBars are bonded into the slots with Helifix HeliBond cementitious grout. A deep masonry beam is formed above the window which supports the masonry and spreads the structural loads. Generally, Helifix DryFix remedial ties or grouted Helifix CemTies are then installed vertically up through the brickwork and into the new masonry beam to secure the existing lintel. No mechanical supports are required and the existing window frame can be removed and replaced without fear of the masonry moving.